- Author Maria Gibbs gibbs@autolifeadvice.com.

- Public 2023-12-16 03:05.

- Last modified 2025-01-22 17:48.

After an overhaul of the engine, it is imperative to run it in in a gentle mode: do not exceed the set speed threshold and the number of revolutions, avoid sudden loads. This is necessary for the gradual grinding of the moving parts of the motor.

During the overhaul of the engine, a complete or partial replacement of a number of moving elements is carried out. Due to imperfect grinding of parts, significant damage to the metal surface is possible under high load. Grinding and fitting can be done in the best way directly at the installation site: at low loads, the metal parts rub tightly, which is why their rapid wear and deformation do not occur in the future. Depending on the degree of intervention in the engine design during overhaul, the run-in mode and its duration may vary.

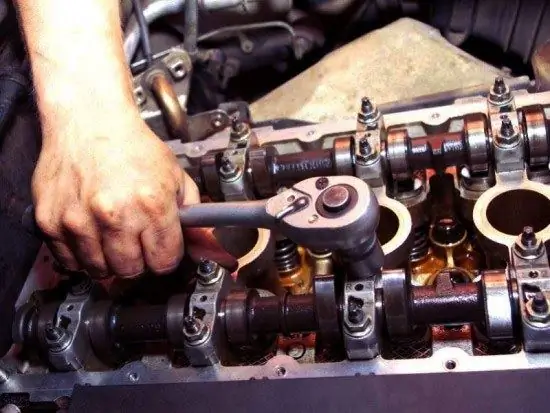

Valve and gas distribution system

The new intake-exhaust system has a vulnerability in the places where the valve shoulders adhere to the seats. Over time, shrinkage and microscopic deformation of the metal occurs, accompanying a slight increase in compression. Also, during running-in, the moving elements of the chain drive, spring returns and camshaft pushers are lapped. In general, about 500 kilometers of run in a gentle mode is enough to run in these units.

Connecting rod-piston system

When repairing a piston system, there are much more nuances. After the simultaneous replacement of the piston rings and liners, the running-in is carried out within 1500-2000 kilometers. A much more difficult situation arises when the rings or liners are changed separately. At the same time, elements already wiped off at one angle produce uneven abrasion of others, due to which the engine's working life is significantly reduced. For example, newly installed rings with partially worn liners cling to miniature grooves, sills and grooves, destroying them even more. The rings themselves are also subject to severe wear.

The connecting rod drive elements are rarely changed in the assembly, so you can often observe a loose fit of the connecting rod leg on the crankshaft or too tight the head stroke relative to the piston. These defects are almost completely eliminated by running in. For 1000 kilometers of run, the movable units take the required shape, grinding a little in places of increased friction.

Features of engine care during running-in

During engine break-in after overhaul, the condition and oil level must be carefully monitored. The first replacement is done after 500 kilometers, the subsequent ones are performed with approximately the same duration, which depends on the type of engine and the recommendations of specialists. Immediately after the completion of running-in, the engine must be serviced in a specialized workshop.