- Author Maria Gibbs gibbs@autolifeadvice.com.

- Public 2023-12-16 03:05.

- Last modified 2025-01-22 17:48.

Loss of power by the engine, deterioration in other performance can be caused by a wide variety of reasons, among which contamination of the injectors plays an important role. However, in order to know for sure, it is necessary to check these elements of the fuel system.

The consequences of contamination of the injectors can be expressed in increased fuel consumption, power drops when the accelerator pedal is pressed sharply, and engine idling instability. Another indirect sign is an increased idle speed and a difficult start. All of the above flaws indicate that it makes sense to check the serviceability of the injectors. This can be done directly on the engine.

Training

Disconnect the negative terminal from the storage battery; for the convenience of further work, you will have to remove the air filter. To do this, use a screwdriver (or just your finger) from below to squeeze the plastic latch and disconnect the wire block from the air flow sensor.

Next, you need to loosen the clamp located on the pipe connecting the filter housing and the inlet pipe. From the bottom of the cross member of the radiator frame, use your fingers to squeeze a pair of rubber mounts under the filter. Now you can lift the front of the filter, squeeze its rear support out of the hole and remove the entire housing.

With the filter removed, you can disconnect the hose from the fuel pressure regulator. Next, squeeze the plastic throttle latch to disconnect the wire harness. Disconnect the block from the idle speed regulator in the same way. Disconnect the injector block from the common wiring harness.

Checking injectors on the VAZ2110

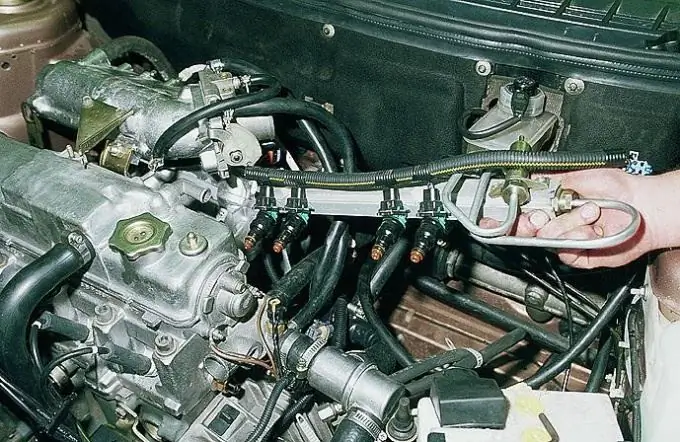

Now you need to tighten the rail mounting bolts and the screws holding the fuel pipe holder. Next, carefully slide the ramp to the side and pull it out together with the injectors. Prepare small transparent containers (for example, cuttings from plastic bottles) that you want to hang directly on the ramp, one under each nozzle. The next step is to check the quality of fuel atomization. Connect the negative terminal of the battery and ask the assistant to turn the starter.

Observe the spraying process: the correct cone should be obtained, while the volume of fuel in all 4 containers should be the same. If any injector does not meet these conditions, it must be replaced. When you turn off the ignition, inspect the injectors: leaking fuel on the nozzles also indicates a malfunction of the part. One of the reasons for the malfunction is a violation of the integrity of the winding. To check this, use an ohmmeter. The device should show a resistance of 11-15 ohms. If this is not the case, then the part needs to be replaced.