- Author Maria Gibbs gibbs@autolifeadvice.com.

- Public 2023-12-16 03:05.

- Last modified 2025-01-22 17:47.

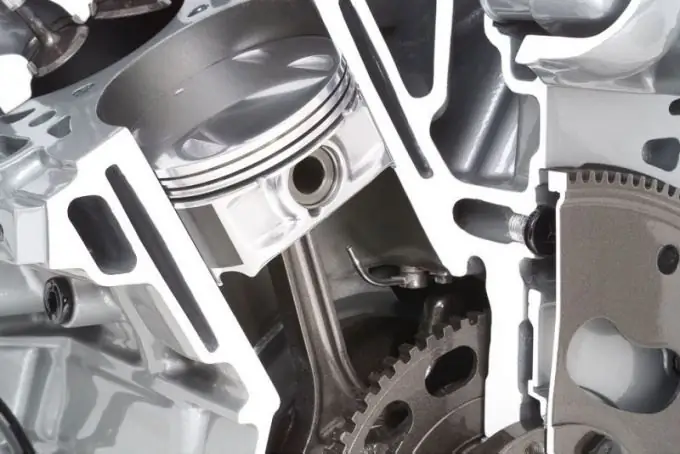

In order to compensate for thermal expansion of the valves, the engine design provides for a gap between the end of the valve stem and the camshaft cam. If this gap is higher than the norm, the valve will not fully open, if it is below the norm, the valve will not close completely.

It is necessary

- - a set of automotive tools;

- - blade probes;

- - crankshaft ratchet wrench.

Instructions

Step 1

Adjust the thermal clearances between the rocker arms and the valves on a cold ZMZ-402 engine. In this case, the fastening nuts of the head of the block and the struts of the axle of the rocker arms must be tightened with the required force. Remove the air filter housing and carburetor. Disconnect the crankcase exhaust pipe. Disconnect the ignition distributor sensor vacuum regulator pipe.

Step 2

Remove the rocker arm cover (block head cover) by unscrewing the 6 bolts of its fastening. Set the piston of the first cylinder to the top dead center (TDC) of the compression stroke. To do this, turn the crankshaft until the third mark of its pulley aligns with the pointer on the gear cover. Rotate the crankshaft using a special wrench installed on its ratchet.

Step 3

Make sure that the inlet and outlet valves are fully closed in this position and that the rocker arms rotate freely. Check the gap between the rocker arm and the valve with a feeler gauge. The clearance for all intake valves should be 0.4-0.45 mm. The clearance for the exhaust valves of the first and fourth cylinders should be 0.45-0.4 mm, for the second and third cylinders 0.4-0.45 mm. With a normal gap, the probe should enter the gap with little resistance.

Step 4

If the clearance requires adjustment, loosen the jam nut on the adjusting screw with a suitable wrench. At the same time, use a different key to hold the adjusting screw against spontaneous rotation. Adjust the gap by slowly turning the adjusting screw while continuously checking the gap. After finishing the adjustment, tighten the adjusting screw with the lock nut. At the same time, again, hold it with a key against accidental displacement. Recheck the clearance. In the same way, adjust the clearance of the other valve of the first cylinder.

Step 5

Crank the engine 180 degrees and adjust the valve clearances on the second cylinder using the above procedure. Then crank the crankshaft another 180 degrees and adjust the valve clearances of the fourth cylinder. After that, turn the crankshaft 180 degrees again and adjust the valve clearances of the third cylinder.