- Author Maria Gibbs [email protected].

- Public 2023-12-16 03:05.

- Last modified 2025-01-22 17:47.

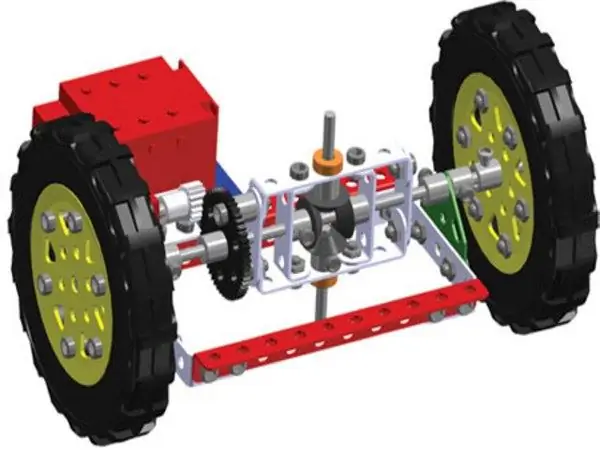

A differential is a device that divides the torque of the input shaft between the axle shafts, regulates the speed of rotation of the wheels. At the moment of turning, the outer wheel travels an arc longer than the inner one, therefore the turn occurs with slipping. To prevent this from happening, a differential is used, thanks to which the wheels rotate at different angular speeds. In order for this mechanical device to work in different road conditions, it is regulated, adjusted to a specific route.

It is necessary

- - a checking polished plate;

- - pointer indicator;

- - moment 25 N • m.

Instructions

Step 1

In order to perform differential adjustment, you must perform a number of the following steps. Press the outer ring of the bearing into the crankcase together with the washer installed under it (the thickness of the washer is 1.0 mm). Remember: the washer must always be 1.0 mm thick.

Step 2

Press the bearing ring into the crankcase on the other side, this time without the washer. Since the bearing rings are manufactured as a set, it is necessary to use them only as a set.

Step 3

Install the differential inside the crankcase and connect both halves with bolts. First knock out the dowel pins, then tighten the bolts using a torque of 25 N • m.

Step 4

Install a surface plate marked VW 385/17 on the differential. If not, use a finely ground surface plate, provided it is sized to fit the flange hole. The dial indicator must be installed so that the measuring font has a fit on the plate, then set the pretension on the indicator. It should correspond to 1.0 mm.

Step 5

Now the differential should be variably moved in both directions. At the same time, observe the readings of the device. Note that the thickness of the other expansion washer increases by approximately 0.30 mm (in this case, pretensioning occurs).

Step 6

Remove the crankcase, then press out the bearing ring. Now install the calculated shim and press in the bearing ring.