- Author Maria Gibbs gibbs@autolifeadvice.com.

- Public 2023-12-16 03:05.

- Last modified 2025-01-22 17:48.

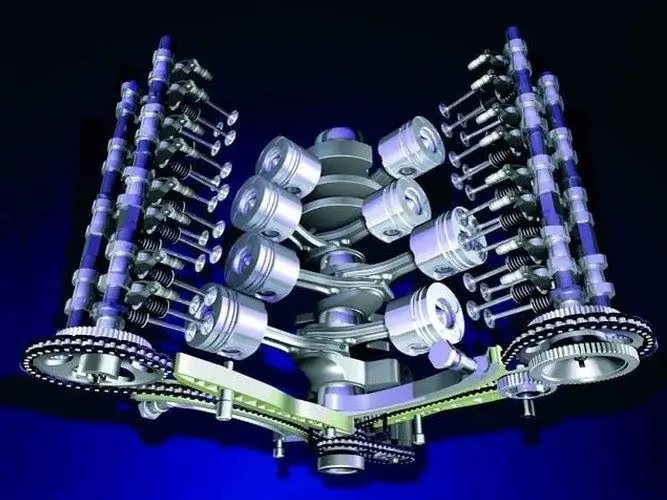

If during the operation of the car engine there is an unusual noise, tapping, and also an increase in gasoline and oil consumption with a loss of power, this may indicate serious malfunctions in the engine. To make a motor, you must first diagnose it.

Instructions

Step 1

Check the compression pressure in the cylinders to determine the condition of the piston system. This is done using a compressometer. Then compare the resulting number with the requirements of the specifications: a low pressure indicates possible wear on the bearings and / or hydraulic pump.

Step 2

Remove the cylinder block, rinse thoroughly and dry it with pressurized air. Inspect the block and especially the oil passages. If it has cracks, you need to purchase a new one.

Step 3

Determine the presence or absence of deformation of the mating plane of the cylinder block using a ruler. To do this, set the ruler diagonally and along the axes of the plane. If the plane is curved more than 0.1 mm, the cylinder block needs to be replaced.

Step 4

Check the tightness of the cylinder block. Close the holes of the cooling jacket, fill it with warm water (20-30 ° C) under a pressure of 0.3 MPa. Wait a few minutes, if no water appears, therefore, the tightness is okay.

Step 5

Measure the diameters of the cylinders with an internal gage in the longitudinal and transverse directions. The difference in dimensions in the upper and other belts shows the amount of wear on the cylinders. When worn down to 0.15 mm, the cylinders must be honed. If the wear is greater than 0.15 mm, the cylinders need to be bored.

Step 6

Replace the piston rings and, if necessary, order the groove of the cylinder mirrors from the auto repair shop, since this cannot be done independently and efficiently. At the same time, order the installation of new pistons of the correct size.

Step 7

Install new connecting rod bearings as they are always in poor condition when the engine is overhauled. If the crankshaft journals are worn out, they must also be replaced.